5. ESonix Model¶

5.1. Download our latest model template¶

- basic template: http://www.aero-sonix.com/static/support/ESonix_template.xlsx

- basic template: http://www.aero-sonix.com/static/support/ESonix_template_dynamical.xlsx

5.2. What is a decompression model?¶

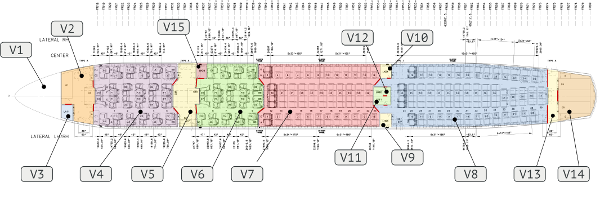

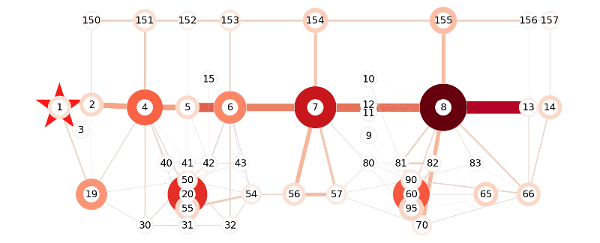

Nothing more than a bunch of volumes connected through vents! You can figure your A/C Layout:

As being a network of volumes:

Creating a model is just matter of describing this network, in terms of volumes and vents.

Additionally, some data about load cases need to be provided. By load case, we mean opening to ambient.

How to fill the model template¶

This document describes how to build a reliable model. As of now, model are described via an excel spreadsheet embedding at least three tabs:

- Load_Cases (mandatory)

- Volumes (mandatory)

- Connections (mandatory)

Additionally, the following tabs may be included:

- Dyn_Attributes (optional)

Warning

tabs name and columns headers are case-sensitive.

Note

Additional tabs are allowed and will be ignored.

5.3. tab “Load_Cases”¶

This tab is mandatory.

Load cases define the different opening holes to simulate. Besides the opening holes themselves, load cases also define the opening hole’s discharge coefficient and the differential pressure.

Parameters¶

| description | default | units | |

|---|---|---|---|

| id | Load Case ID | mandatory | no units |

| vol_i | ID of Exploded Volume(s) | mandatory | no units |

| opening_hole | Raw opening area | mandatory | [m^2 | in^2] |

| cp | Discharge coefficient | mandatory | no units |

| altitude | Flying altitude | blank | [m | in] |

| pressure_coeff | Aircraft pressure coefficient | 0 | no units |

| mach_number | Aircraft mach number | 0 | no units |

| p_atm | Atmosphere pressure value | blank | [bar | psi] |

| t_cabin | Cabin initial temperature | 296 | [K] |

| p_cabin | Cabin initial pressure | mandatory | [bar | psi] |

| label | Load Case label | mandatory | no units |

Load_Cases/id¶

flags:

- Type: Int in range [1; +∞]

- Default: None

- Mandatory: True

- Unique: True

Short description:

Load Case ID [no units]

Load_Cases/vol_i¶

flags:

- Type: Str

- Default: None

- Mandatory: True

- Unique: False

Short description:

ID of Exploded Volume(s) [no units]

The vol_i parameter refers to the exploded volume, the one beeing

connected to the ambient. Two kinds of parameters are allowed:

- and integer refering to an existing volume ID

- a string “<id1> + <id2> [ + <idn>...] refering to existing volume IDs

When volume IDs are summed, ESonix will automatically merge those volumes and reroute connections.

Load_Cases/opening_hole¶

flags:

- Type: Float in range ]0; +∞]

- Default: None

- Mandatory: True

- Unique: False

Short description:

Raw opening area [m^2] or [in^2]

Opening hole is defining the connection to the ambient. It is defined by FAR25.365e as a function of the fuselage diameter. You can use the toolbox to calculate it: http://www.aero-sonix.com/toolbox/opening_hole

Load_Cases/cp¶

flags:

- Type: Float in range [0; 1]

- Default: None

- Mandatory: True

- Unique: False

Short description:

Discharge coefficient [no units]

Load_Cases/altitude¶

flags:

- Type: Float in range [0; +∞]

- Default: nan

- Mandatory: False

- Unique: False

Short description:

Flying altitude [m] or [in]

The interesting value for a load case is mainly the differential pressure between the cabin pressure and the ambient pressure. Knowing the cabin pressure from aircraft manuals, or taking conservatively one atmosphere, the ambient pressure is still missing.

This ambient pressure can be calculated from a “standard atmosphere” at a given altitude. Such a tool is provided in the toolbox: http://www.aero-sonix.com/toolbox/by_altitude .

Load_Cases/pressure_coeff¶

flags:

- Type: Float in range [0; +∞]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Aircraft pressure coefficient [no units]

Load_Cases/mach_number¶

flags:

- Type: Float in range [0; +∞]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Aircraft mach number [no units]

Load_Cases/p_atm¶

flags:

- Type: Float in range [0; +∞]

- Default: nan

- Mandatory: False

- Unique: False

Short description:

Atmosphere pressure value [bar] or [psi]

Load_Cases/t_cabin¶

flags:

- Type: Float in range [0; +∞]

- Default: 296

- Mandatory: False

- Unique: False

Short description:

Cabin initial temperature [K]

Load_Cases/p_cabin¶

flags:

- Type: Float in range [0; +∞]

- Default: None

- Mandatory: True

- Unique: False

Short description:

Cabin initial pressure [bar] or [psi]

Load_Cases/label¶

flags:

- Type: Str

- Default: None

- Mandatory: True

- Unique: False

Short description:

Load Case label [no units]

Preprocessing¶

Besides the usual units conversions, ESonix will process load cases as follows:

If p_atm is not given, Atmospheric pressure will be calculated by altitude,

and optionnally mach_number and pressure_coeff.

Merged Load Cases¶

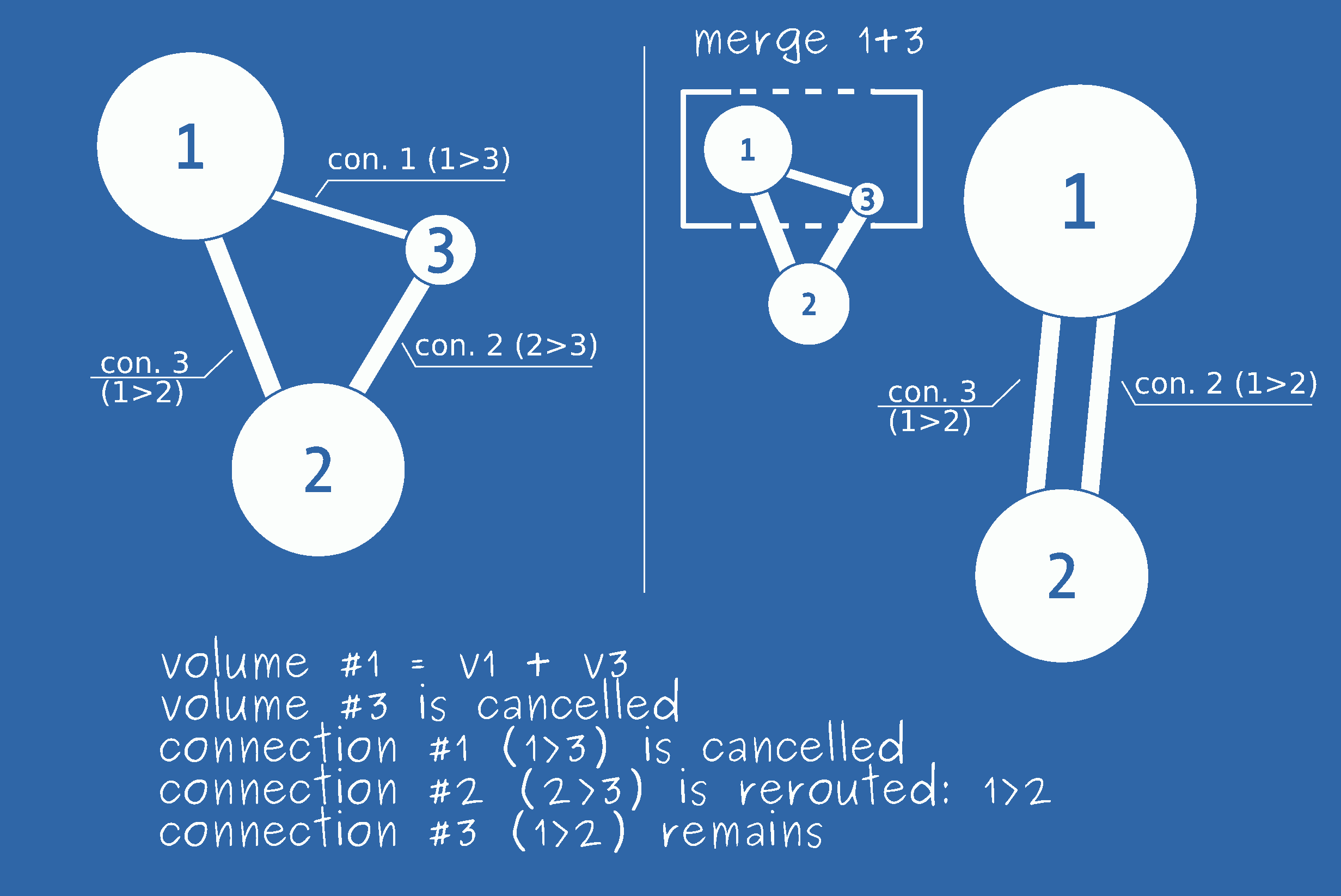

A special attention is taken by ESonix to handle automatically and transparently the merged load cases.

If ``raw_merging`` option is off (as set by default), when the explosion occurs in some (two or more) merged volumes, (cf. LC_vol_i parameter), ESonix will internally change the provided model by cancelling highest IDs merged volume(s). To do so, ESonix will sum all the merged volumes, change the lowest ID volume to match the new volume summed, and cancel the rest of the merged volumes.

For example, let say a load case merge volumes 1 and 3, ESonix will change volume 1 (lowest ID) such as its volume’s value match the sum of volume 1 and volume 3. Esonix will then cancel volume 3.

More over, ESonix will also automatically reroute connections to match the new layout, as explained in Fig. 5.3.

Once the model is reinitialized (don’t forget to check the analysis logs to check what ESonix did!), calculations are performed using the new modified models. When storing results on disk, ESonix will then map the results (new volumes, new connections) to regular existing volumes and interfaces, such as results data mapping will be transparent to the user.

As an illustration for interface 2/3 is:

- \(P_3(t)=P_1(t)\)

- \(T_3(t)=T_1(t)\)

- \(\Delta_{P_{2(2>3)}}(t)=-\Delta_{P_{2(1>2)}}(t)\)

- \(\dot{m}_{2(2>3)}(t)=-\dot{m}_{2(1>2)}(t)\)

- and so on...

Note

The negative sign for \(\Delta_P\) and \(\dot{m}\) comes with the inversion of the connection: [2>3] = -[3>2]

User would therefore have a transparent access to \(\Delta_{P_{2/3}}\) although this interface does not exist for such a merged load case.

If ``raw_merging`` option is on, ESonix will not remap values and results would therefore present raw results, as calculated by ESonix.

Note

The raw_merging option is new starting from version 2.3. Previous

ESonix versions were showing results as if this option was “on”, therefore,

previous ESonix version were showing raw values.

5.4. tab “Volumes”¶

This tab is mandatory.

Volumes are the base parameters for a model decompression. They act as a tank of air. This air has a given pressure and temperatures at initial conditions, when t=0 sec.

As soon as one of the volume is connected to the ambient, the air located in the different volumes will be sucked by the ambient, leading to pressure on partitions.

Parameters¶

| description | default | units | |

|---|---|---|---|

| id | Volume ID | mandatory | no units |

| label | Volume label | mandatory | no units |

| deck | Deck Location | mandatory | no units |

| group | Group (sub-deck) identification for Unified Model | blank | no units |

| sta | Station | mandatory | [m | in] |

| rbl | RBL | mandatory | [m | in] |

| volume | Volume (size value) | mandatory | [m^3 | in^3] |

| deor | Deck Explosion Occupation Rate | 0.0 | no units |

| veor | Volume Explosion Occupation Rate | 0.0 | no units |

Volumes/id¶

flags:

- Type: Int in range [0; +∞]

- Default: None

- Mandatory: True

- Unique: True

Short description:

Volume ID [no units]

Volumes/label¶

flags:

- Type: Str

- Default: None

- Mandatory: True

- Unique: False

Short description:

Volume label [no units]

Volumes/deck¶

flags:

- Type: Int in range [-1; 2]

- Default: 0

- Mandatory: True

- Unique: False

Short description:

Deck Location [no units]

The mandatory deck parameter is used for organizing the results only and

has no effects on calculations themselves. An integer is to be provided as per

deck location, knowing by default:

deck==-1: volume located in the cargodeck==0: volume located at the main deckdeck==1: volume is a ceiling compartmentdeck==2: volume is on the second deck (in case of dual deck body)

Volumes/group¶

flags:

- Type: Int in range [-∞; +∞]

- Default: nan

- Mandatory: False

- Unique: False

Short description:

Group (sub-deck) identification for Unified Model [no units]

Volumes/sta¶

flags:

- Type: Float in range [-∞; +∞]

- Default: 0

- Mandatory: True

- Unique: False

Short description:

Station [m] or [in]

Volumes/rbl¶

flags:

- Type: Float in range [-∞; +∞]

- Default: 0

- Mandatory: True

- Unique: False

Short description:

RBL [m] or [in]

Volumes/volume¶

flags:

- Type: Float in range ]0; +∞]

- Default: None

- Mandatory: True

- Unique: False

Short description:

Volume (size value) [m^3] or [in^3]

Volumes/deor¶

flags:

- Type: Float in range ]-1; 1[

- Default: 0.0

- Mandatory: False

- Unique: False

Short description:

Deck Explosion Occupation Rate [no units]

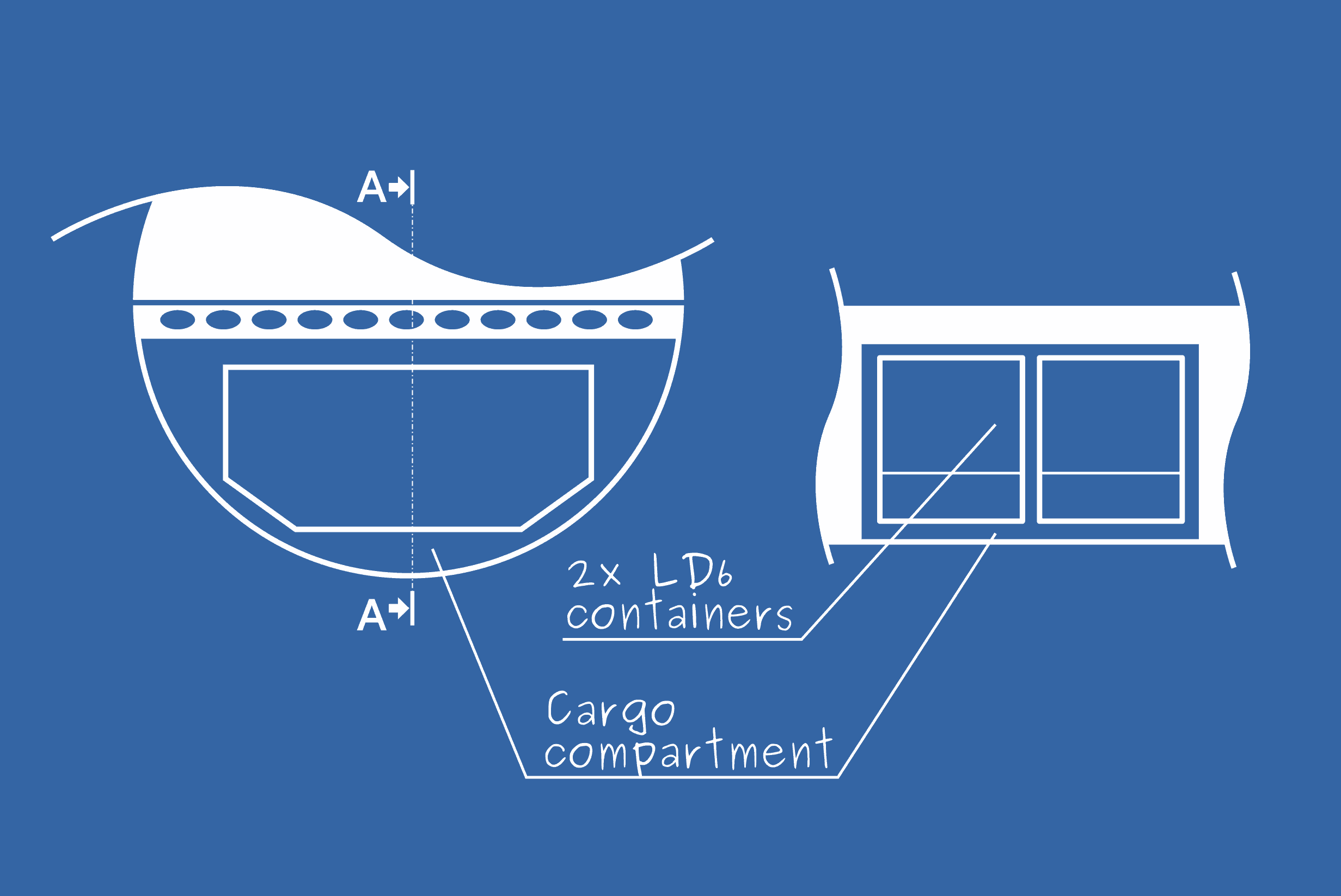

DEOR stands for “Deck Explosion Occupation Rate” and defines how the volume is reduced when the explosion occurs somewhere in the same deck as the given volume. For example, this parameter is useful to initialize the cargo volumes with container inside when explosion occurs in the cargo.

Volumes/veor¶

flags:

- Type: Float in range ]-1; 1[

- Default: 0.0

- Mandatory: False

- Unique: False

Short description:

Volume Explosion Occupation Rate [no units]

VEOR stands for “Volume Explosion Occupation Rate” and defines how the volume is reduced when the explosion occurs in the volume itself.

See also

Tutorial #4 uses “VEOR” parameter in the section Unified model.

Preprocessing¶

Right before the actual run is solved, the model the user uploaded is preprocessed. For the volumes, it consists in setting blank cells to default values as defined in Volumes parameters.

Common examples¶

Volume reduction for a cargo compartment using DEOR¶

Volumes are really easy to idealize. Nevertheless, we will illustrate the use

of the DEOR parameter.

A regular LD-6 cargo container has an internal volme of 8.9m³.Let say that a cargo compartment has a volume of 25m³ and can therefore welcome two containers, as shown in Fig. 5.4.

It may be interesting to simulate the A/C with cargo empty for an explosion occuring in the cabin, and cargo occupied for an explosion in the cargo. Instead of creating two models, run two analysis and compare them, it is more convenient to inform ESonix of the expected behavior.

Setting DEOR will inform ESonix that, when the explosion occures in the cargo,

then the volumes of the cargo should be reduced by the DEOR factor.

If DEOR is null or blank, no reduction will therefore be applied.

In the current example, the volume occupied by the two containers is \(8.9 \times 2 = 17.8m^3\). Assuming that the both containers are full, the volume of air available is therefore \(25-17.8=7.2m^3\). The initial volume of air is therefore reduced by the DEOR coefficient \(DEOR=1 - \frac{7.2}{25}=0.712\)

| Column | User input | Preprocess | Actual input |

|---|---|---|---|

id |

9 | 9 | |

volume |

25 | 25 | |

label |

“cargo example” | “cargo example” | |

deck |

-1 | -1 | |

sta |

5 | 5 | |

rbl |

0 | 0 | |

deor |

0.712 | 0.712 | |

veor |

Default to zero | 0 |

5.5. tab “Connections”¶

This tab is mandatory.

A connection is connecting two volumes between them. Its geometry and behaviour will define how the mass of air in those volumes will be exchanged between them.

Basically, a connection always connect two volumes (aka vol I and vol J) and is therefore located at an interface.

When defining a connection, take care to always set volume I ID to the lowest ID of both volumes.

Example: let say you have two volumes to connect, ID2 and ID7, Volume I will always be volume ID2 and Volume J will always be volume ID7.

See also

Tutorial #2 is dedicated to decompression features whereas Tutorial #3 is dedicated to doors

Parameters¶

| description | default | units | |

|---|---|---|---|

| id | Connection ID | mandatory | no units |

| vol_i | ID of volume I | mandatory | no units |

| vol_j | ID of volume J | mandatory | no units |

| comments | Free text | no units | |

| door | Door Frame Area | 0 | [m^2 | in^2] |

| opening_latency | Feature opening latency time | 0 | [sec] |

| vent_area_i_to_j | Decompression raw area | 0 | [m^2 | in^2] |

| opening_pressure_i_to_j | Pressure Threshold | 0 | [bar | psi] |

| opening_time_i_to_j | Feature Opening Time | 0 | [sec] |

| cp_i_to_j | Discharge Coefficient | 0 | no units |

| vent_area_j_to_i | Decompression raw area | blank | [m^2 | in^2] |

| opening_pressure_j_to_i | Pressure Threshold | blank | [bar | psi] |

| opening_time_j_to_i | Feature Opening Time | blank | [sec] |

| cp_j_to_i | Discharge Coefficient | blank | no units |

| exvar | Exploded Volume Area Reduction | 0 | no units |

| ovar | Occupied Volume Area Reduction | 0 | no units |

Connections/id¶

flags:

- Type: Int in range [1; +∞]

- Default: None

- Mandatory: True

- Unique: True

Short description:

Connection ID [no units]

Connections/vol_i¶

flags:

- Type: Int in range [1; +∞]

- Default: None

- Mandatory: True

- Unique: False

Short description:

ID of volume I [no units]

Connections/vol_j¶

flags:

- Type: Int in range [1; +∞]

- Default: None

- Mandatory: True

- Unique: False

Short description:

ID of volume J [no units]

Connections/comments¶

flags:

- Type: Str

- Default:

- Mandatory: False

- Unique: False

Short description:

Free text [no units]

Connections/door¶

flags:

- Type: Float in range [0; +∞]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Door Frame Area [m^2] or [in^2]

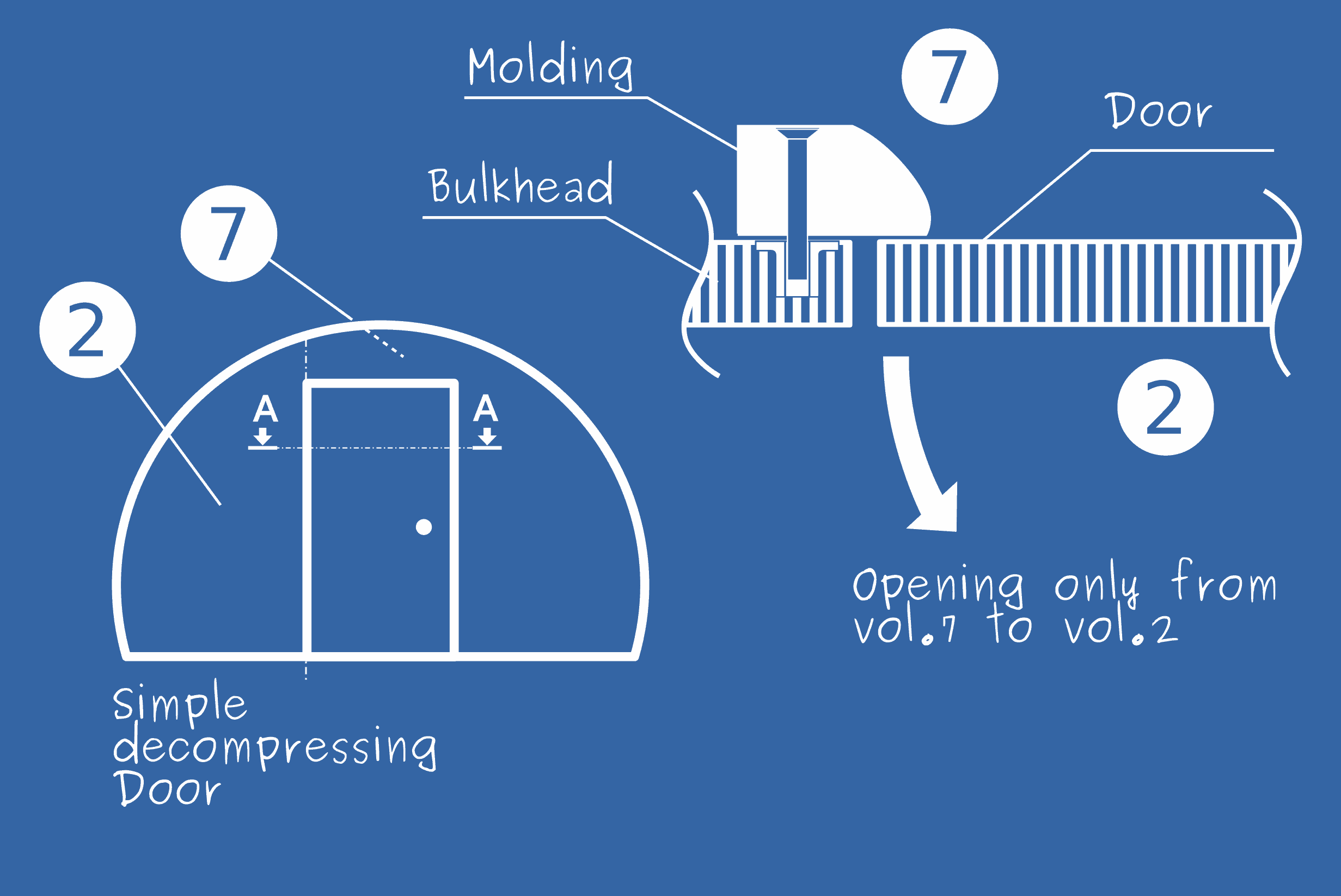

Decompressing Doors are kind of special venting. Two cases exist: or the full door acts as decompression feature, or the door features an internal decompression panel.

In the first case, the door area (door column) needs to be equal to vent_area_*. This is very often the case of swivel doors. If the doors opens only in one direction, the relevant opening_pressure_* need to be set to an unreachable pressure value, such as it will never open.

In the latter case, the door area will be different from the vent_area_*, and necessarly greater.

Note

For all the cases, the door parameter only deals with opened-doors or closed-doors initial conditions. Only the `vent_area` parameters have a dynamical attribute.

Connections/opening_latency¶

flags:

- Type: Float in range [-∞; +∞]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Feature opening latency time [sec]

Connections/vent_area_i_to_j¶

flags:

- Type: Float in range [0; +∞]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Decompression raw area [m^2] or [in^2]

Connections/opening_pressure_i_to_j¶

flags:

- Type: Float in range [0; +∞]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Pressure Threshold [bar] or [psi]

Connections/opening_time_i_to_j¶

flags:

- Type: Float in range [0; +∞]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Feature Opening Time [sec]

Connections/cp_i_to_j¶

flags:

- Type: Float in range [0; 1]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Discharge Coefficient [no units]

Connections/vent_area_j_to_i¶

flags:

- Type: Float in range [0; +∞]

- Default: nan

- Mandatory: False

- Unique: False

Short description:

Decompression raw area [m^2] or [in^2]

Connections/opening_pressure_j_to_i¶

flags:

- Type: Float in range [0; +∞]

- Default: nan

- Mandatory: False

- Unique: False

Short description:

Pressure Threshold [bar] or [psi]

Connections/opening_time_j_to_i¶

flags:

- Type: Float in range [0; +∞]

- Default: nan

- Mandatory: False

- Unique: False

Short description:

Feature Opening Time [sec]

Connections/cp_j_to_i¶

flags:

- Type: Float in range [0; 1]

- Default: nan

- Mandatory: False

- Unique: False

Short description:

Discharge Coefficient [no units]

Connections/exvar¶

flags:

- Type: Float in range [-∞; +∞]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Exploded Volume Area Reduction [no units]

EXVAR stands for “EXploded Volume vent Area Reduction”. Like “OVAR”, “EXVAR” defines a way to dynamically recalculate the vent area between two volumes when one of the connected volumes (I or J) is the volume where the explosion occurs.

If one of the connected volumes is the one where the explosion occurs, the “i to j” and “j to i” venting area are reduced as follows:

Connections/ovar¶

flags:

- Type: Float in range [-∞; +∞]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Occupied Volume Area Reduction [no units]

OVAR stands for “Occupied Volume vent Area Reduction”. The optional column “ovar” (default to 0 if omitted) allows ESonix to dynamically recalculate the vent area for each load case.

This parameter is specially designed to simulate the jam of an opening feature when the incoming volume is occupied. For example, a decompression panel may be blocked by a container in the cargo.

If the connection is leaving an occupied volume (parameters “DEOR” or “VEOR” for the volume #I), the vent area from J to I is reduced by this parameter as follows:

Likewise, if the connection is going to an occupied volume (parameters “DEOR” or “VEOR” for the volume #J), the vent area from I to J is reduced by this parameter as follows:

Preprocessing¶

Right before the actual run is solved, the model the user uploaded is preprocessed. This has a particular meaning for connections and can be described by two different phases:

- Initialisation of the

*_i_to_jcolumns.- Symmetrization of the

*_j_to_icolumns.

Step 1: Initialisation¶

Initialisation deals with the *_i_to_j columns.

This phase does not directly affect the *_j_to_i ones.

For each row of the model, any empty or blank cell within the *_i_to_j

columns will be set to 0.0.

Step 2: Symmetrization¶

Symmetrization deals with the *_j_to_i columns. This phase never

affects the *_i_to_j ones.

This “symmetrisation” process means that connections are assumed symmetric by default.

The user shall fill the *_i_to_j columns. *_j_to_i is not

mandatory. The empty *_j_to_i columns will be automatically copied

from *_i_to_j.

A connection may be partially symmetric. For example, a connection may have the same discharge coefficient (cp) for both ways, but different venting area. In this case, only the asymmetric values need to be filled.

Common examples¶

The following examples show the most common connections and propose the best way to idealize them.

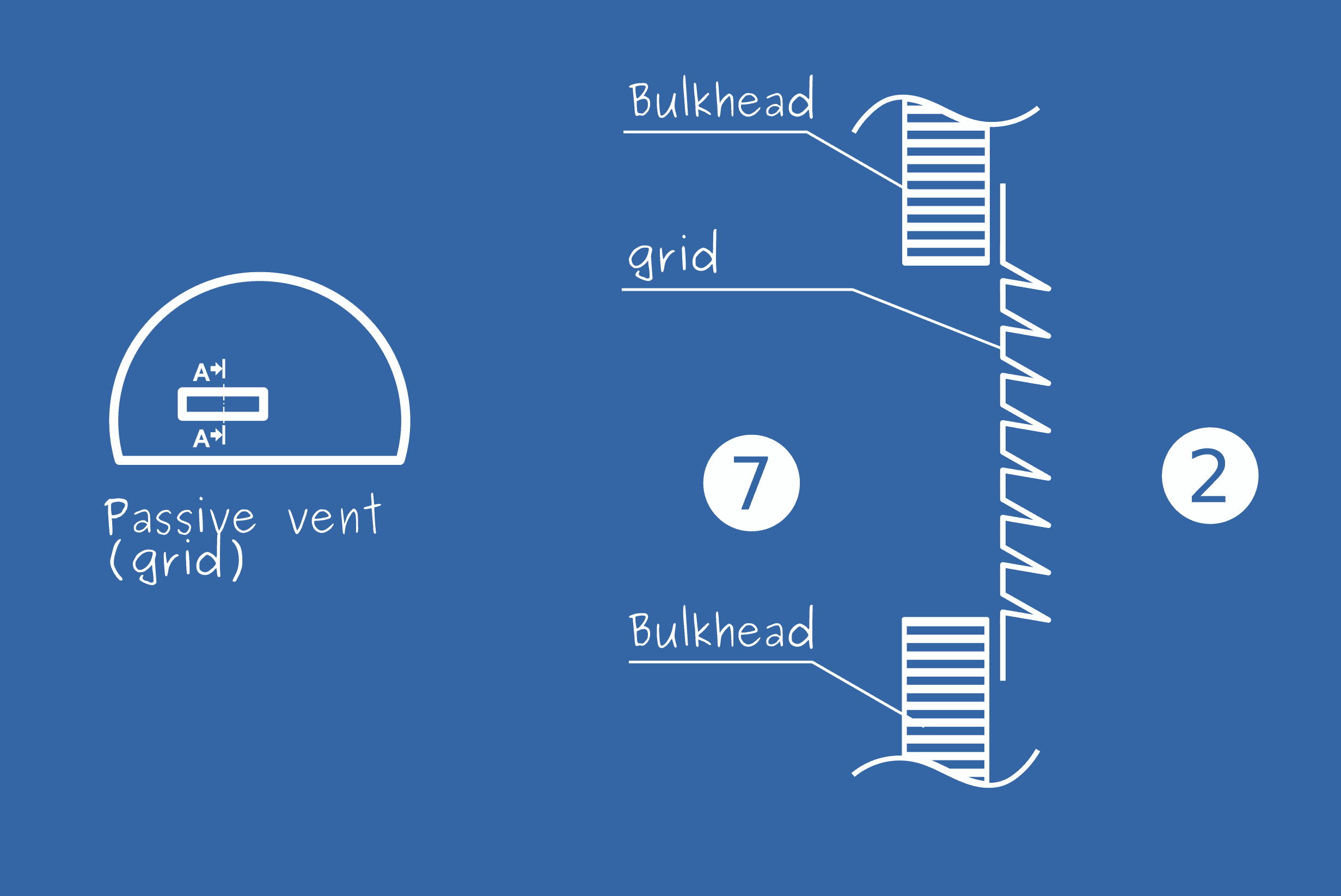

Passive vent¶

Passive vents are the most simple connections. Passive vents are always symmetrical (although you may define unsymmetrical venting area).

Example: A connection (ID19) is a passive vent (symmetric) between volumes 2 and 7. The total vent area is 0.3m^2, with a discharge coefficients of 0.4. Such a feature is shown at Fig. 5.5.

The ESonix pre-process phase would prepare the full connection as described

below (in bold the default values determined by ESonix). Pay attention to the

symmetrization process to fill the _j_to_i columns.

| Column | User input | Preprocess | Actual input |

|---|---|---|---|

id |

19 | 19 | |

vol_i |

2 | 2 | |

vol_j |

7 | 7 | |

door |

Default to zero | 0 | |

opening_latency |

Default to zero | 0 | |

vent_area_i_to_j |

0.3 | 0.3 | |

opening_pressure_i_to_j |

Default to zero | 0 | |

opening_time_i_to_j |

Default to zero | 0 | |

cp_i_to_j |

0.4 | 0.4 | |

vent_area_j_to_i |

Default to vent_area_i_to_j |

0.3 | |

opening_pressure_j_to_i |

Default to opening_pressure_i_to_j |

0 | |

opening_time_j_to_i |

Default to opening_time_i_to_j |

0 | |

cp_j_to_i |

Default to cp_i_to_j |

0.4 | |

comments |

Default to null string | “” | |

ovar |

Default to zero | 0 | |

exvar |

Default to zero | 0 |

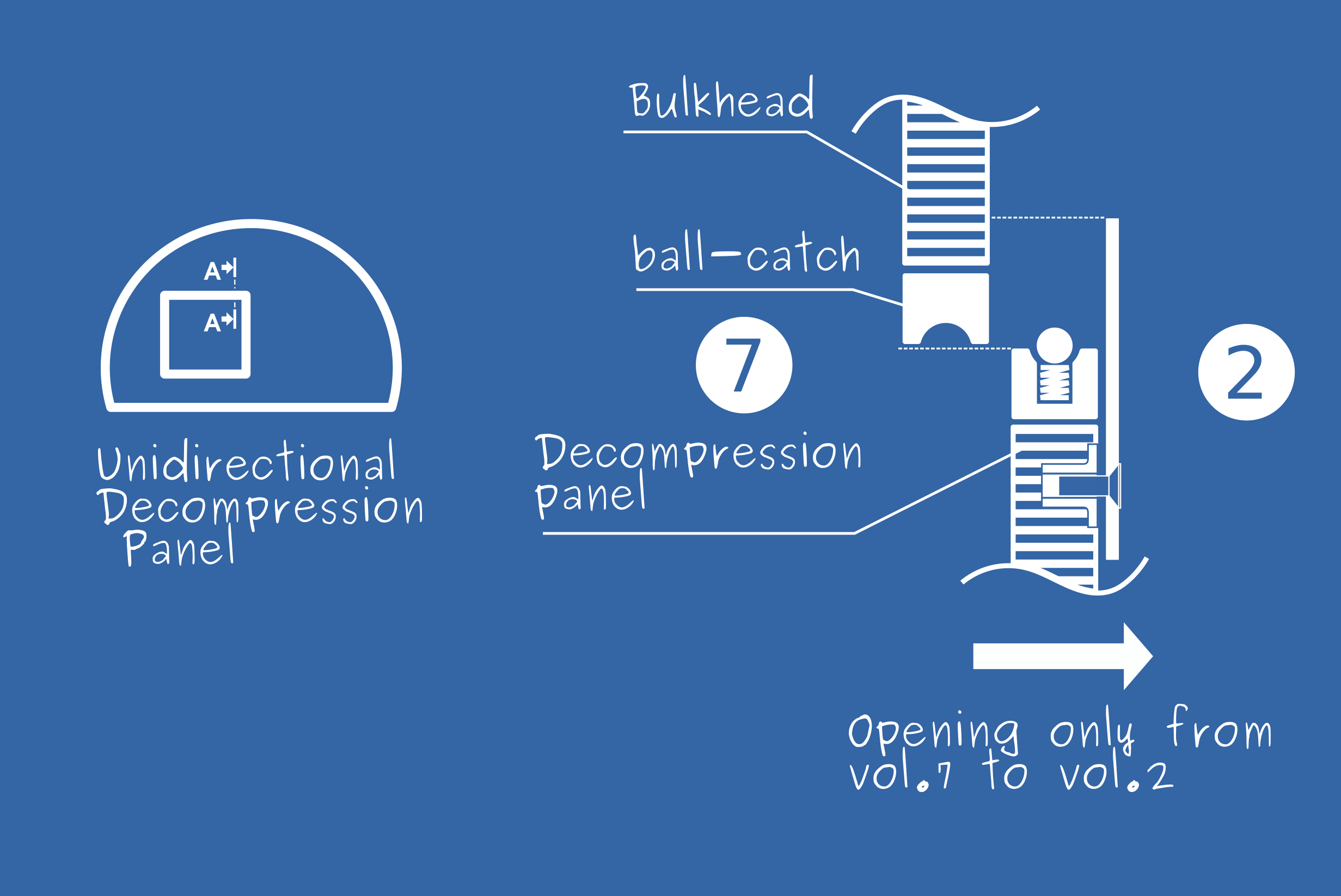

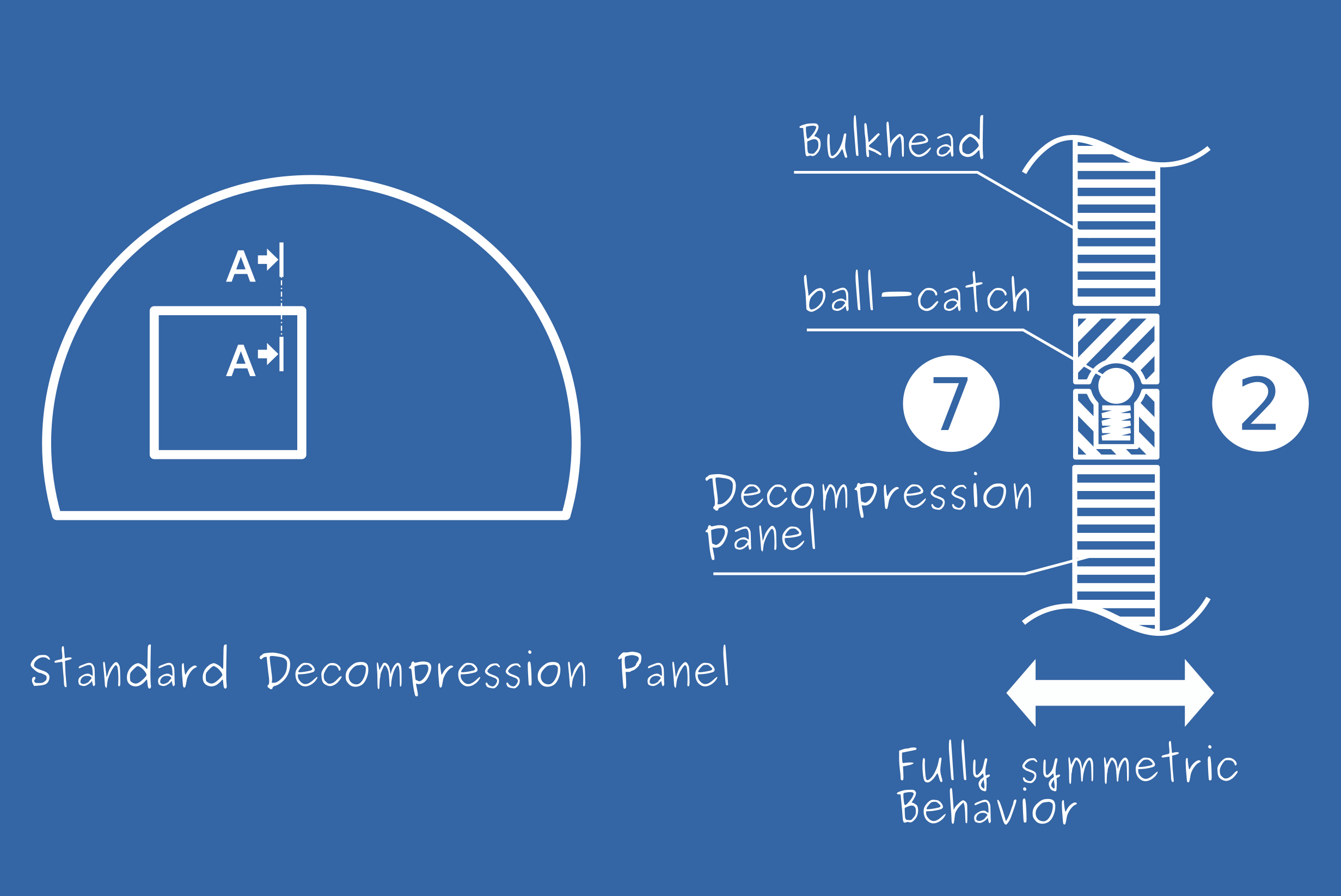

Standard decompression panel (Bi-directionnel)¶

Decompression panels are activated once the delta pressure pushing on it reach a target value. It is most of the time fully symmetric: the same delta pressure threshold triggers the mechanism and the same vent area is cleared.

Fig. 5.6 Standard Decompression panel between volumes 2 and 7 (designed with ball-catch for this particular example)

Example: A decompression panel defines the connection ID19. The total released area is 0.5m^2. The panel opens

for a pressure of 1.5bar, and is assumed to open instantaneously (opening_time = 0).

Such a feature is shown at Fig. 5.6.

The ESonix pre-process phase would prepare the full connection as described

below (in bold the default values determined by ESonix). Pay attention to the

symmetrization process to fill the _j_to_i columns.

| Column | User input | Preprocess | Actual input |

|---|---|---|---|

id |

19 | 19 | |

vol_i |

2 | 2 | |

vol_j |

7 | 7 | |

door |

Default to zero | 0 | |

opening_latency |

Default to zero | 0 | |

vent_area_i_to_j |

0.3 | 0.3 | |

opening_pressure_i_to_j |

1.5 | 1.5 | |

opening_time_i_to_j |

Default to zero | 0 | |

cp_i_to_j |

0.6 | 0.6 | |

vent_area_j_to_i |

Default to vent_area_i_to_j |

0.3 | |

opening_pressure_j_to_i |

Default to opening_pressure_i_to_j |

1.5 | |

opening_time_j_to_i |

Default to opening_time_i_to_j |

0 | |

cp_j_to_i |

Default to cp_i_to_j |

0.6 | |

comments |

Default to null string | “” | |

ovar |

Default to zero | 0 | |

exvar |

Default to zero | 0 |

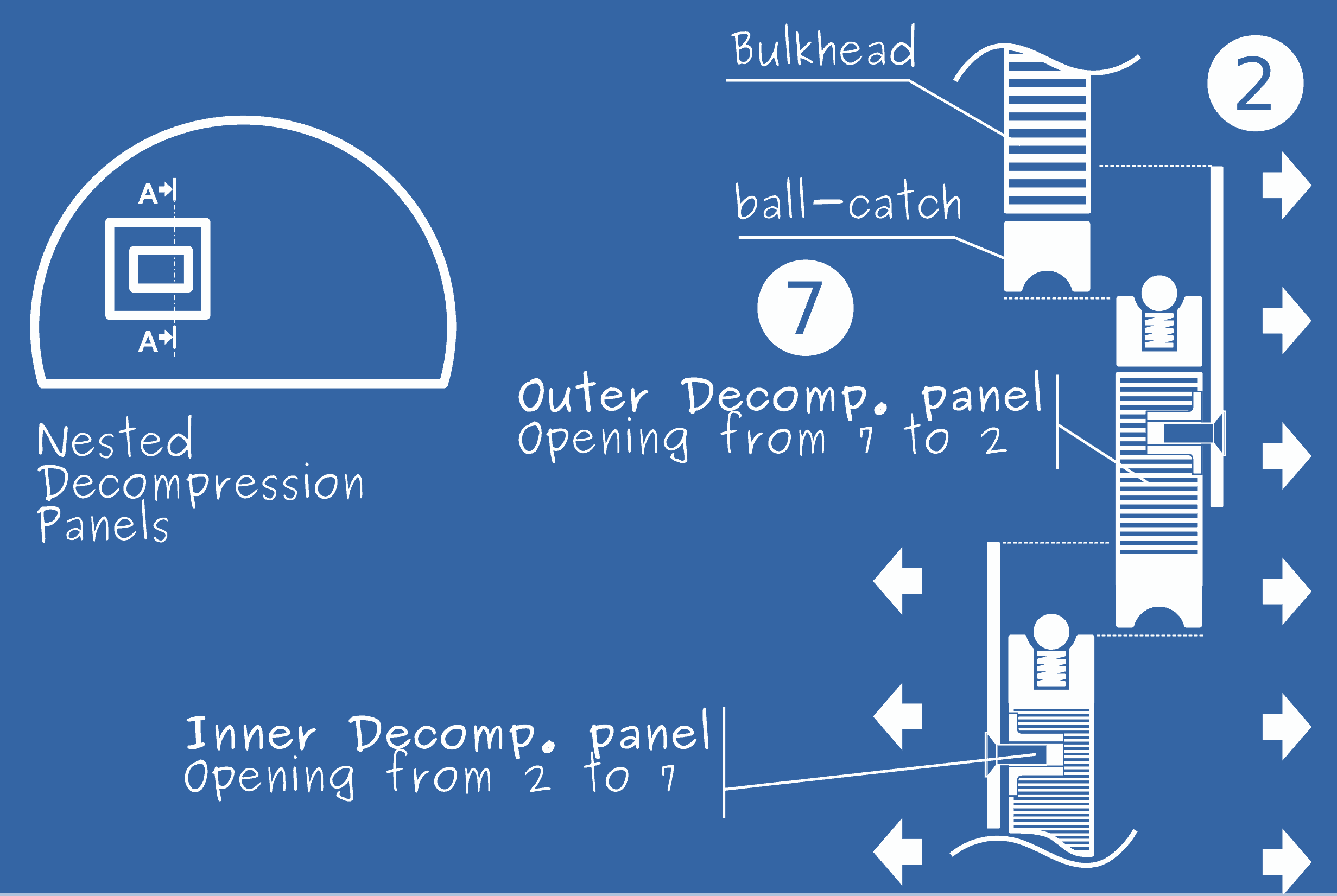

Unidirectional decompression panel¶

Unidirectional decompression panels are activated only for one direction

Example: Same example as above, but the panel can only open from 7 to 2. Such a feature is shown at Fig. 5.7.

One way to achieve this is to reduce vent_area_i_to_j to 0 (no vent area

from 2 to 7), and to set vent_area_j_to_i to 0.3.

| Column | User input | Preprocess | Actual input |

|---|---|---|---|

id |

19 | 19 | |

vol_i |

2 | 2 | |

vol_j |

7 | 7 | |

door |

Default to zero | 0 | |

opening_latency |

Default to zero | 0 | |

vent_area_i_to_j |

Default to zero | 0 | |

opening_pressure_i_to_j |

Default to zero | 0 | |

opening_time_i_to_j |

Default to zero | 0 | |

cp_i_to_j |

0 | ||

vent_area_j_to_i |

0.3 | 0.3 | |

opening_pressure_j_to_i |

1.5 | 1.5 | |

opening_time_j_to_i |

Default to opening_time_i_to_j |

0 | |

cp_j_to_i |

0.6 | 0.6 | |

comments |

Default to null string | “” | |

ovar |

Default to zero | 0 | |

exvar |

Default to zero | 0 |

Note

another way of achieving a unidirectional decompression panel opening would be to set an artificially high opening pressure in the opposite direction.

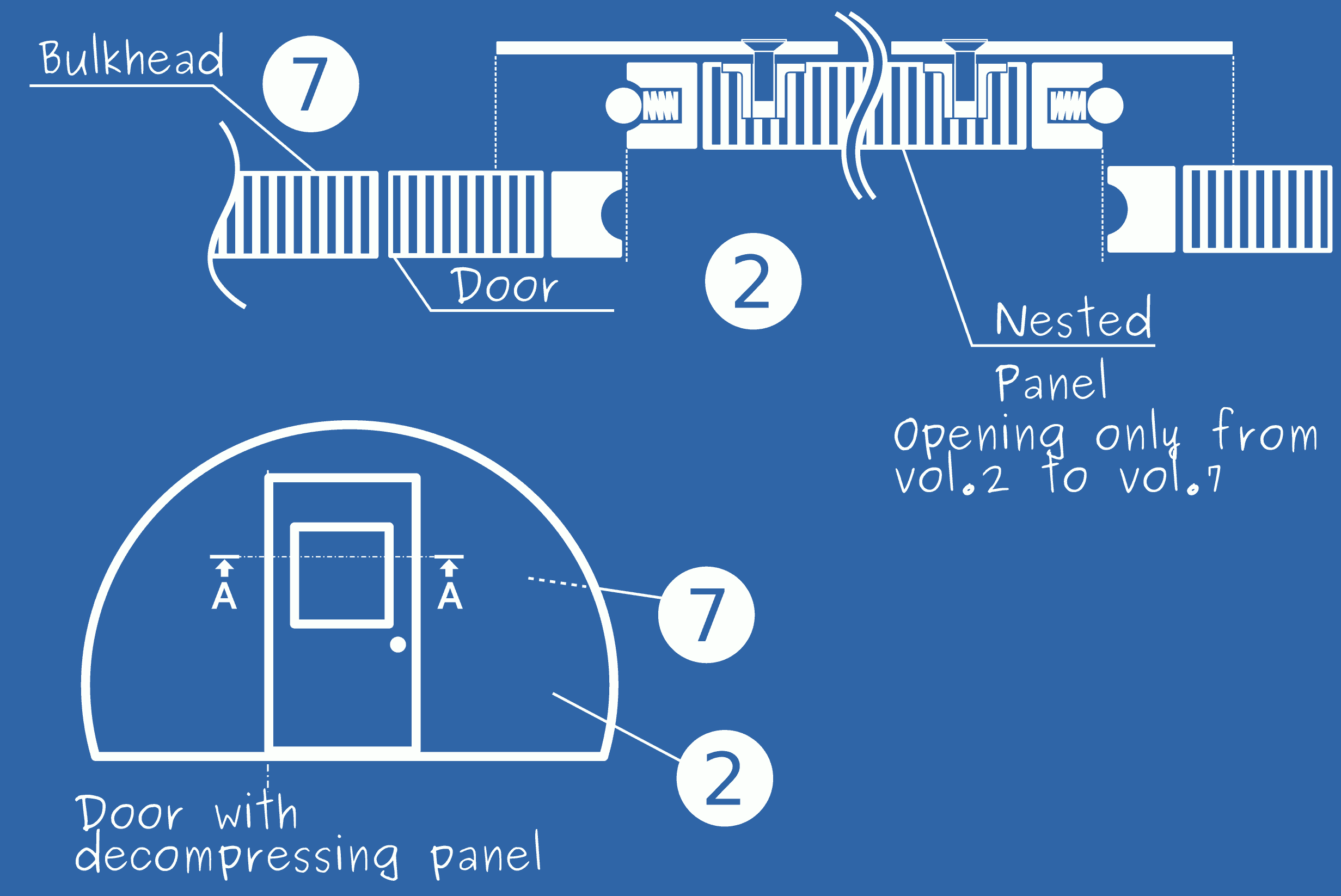

Nested differential decompression panel¶

This particular design is sometimes useful to optimize a decompression layout.

Example. As shown in Fig. 5.8, a decompression feature (let say with ID 23) can open in both directions with the same triggering pressure, but with different area. This would be achieved this way:

| Column | User input | Preprocess | Actual input |

|---|---|---|---|

id |

23 | 23 | |

vol_i |

2 | 2 | |

vol_j |

7 | 7 | |

door |

Default to zero | 0 | |

opening_latency |

Default to zero | 0 | |

vent_area_i_to_j |

0.3 | 0.3 | |

opening_pressure_i_to_j |

1.5 | 1.5 | |

opening_time_i_to_j |

Default to zero | 0 | |

cp_i_to_j |

0.6 | 0.6 | |

vent_area_j_to_i |

0.8 | 0.8 | |

opening_pressure_j_to_i |

Default to opening_pressure_i_to_j |

1.5 | |

opening_time_j_to_i |

Default to opening_time_i_to_j |

0 | |

cp_j_to_i |

Default to cp_i_to_j |

0.6 | |

comments |

Default to null string | “” | |

ovar |

Default to zero | 0 | |

exvar |

Default to zero | 0 |

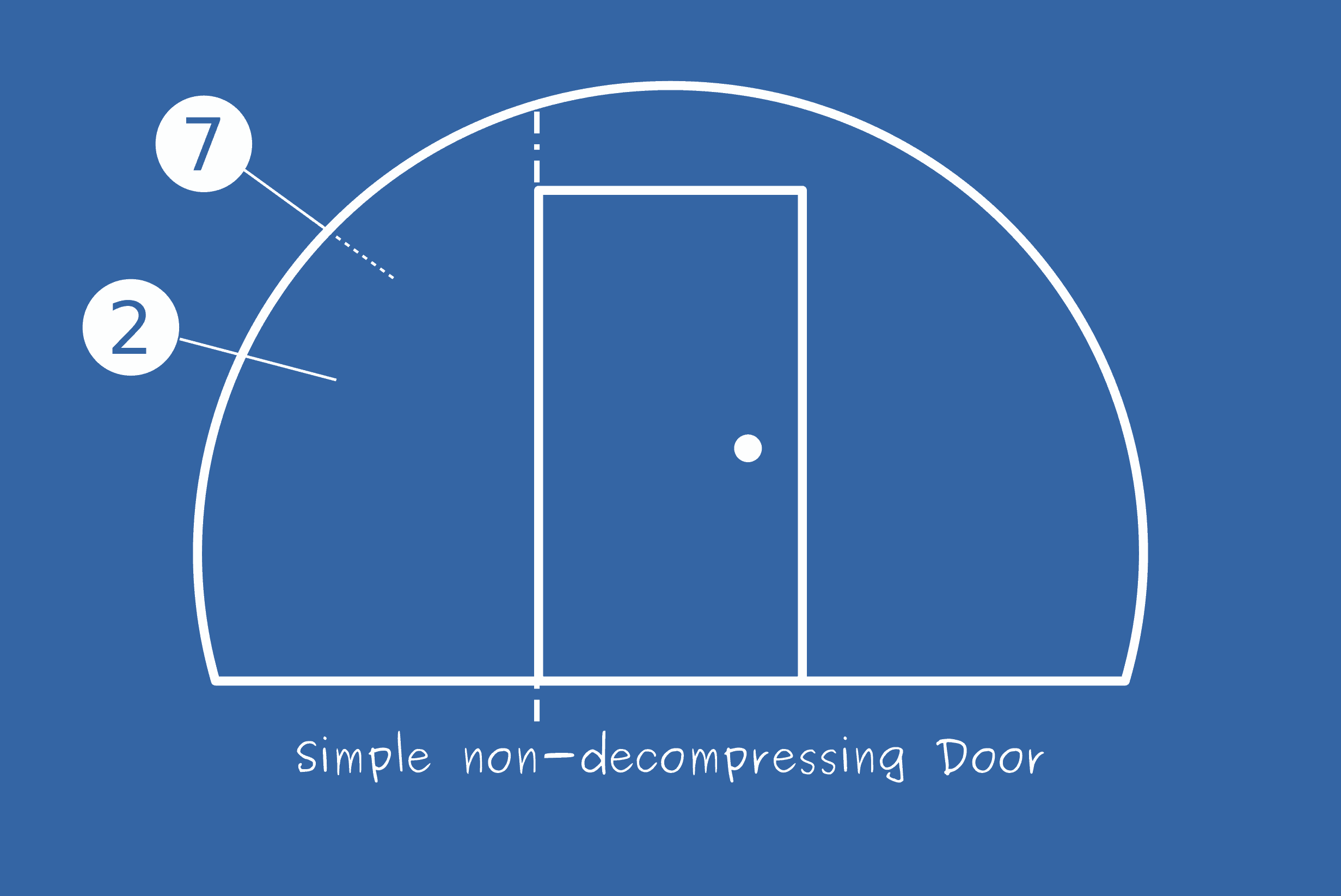

Simple non-decompressing door¶

A non-decompressing door is considered as a passive vent when the opened-doors configuration

is ran. No more data except door and cp_i_to_j are required (beside

id, vol_j and vol_j!)

Example: A simple 2.2m² door (let say ID9) connects compartments 2 and 7 (cf. Fig. 5.9).

Usually, such a big clean vent is assumed to have a discharge coefficient of 0.8. When the decompression analysis is ran with the closed-doors initial conditions, this venting is ignored (the door is closed and will remain closed) whereas for the opened-doors initial conditions, the full door is opened and will remain opened as a 2.2m² passive vent.

| Column | User input | Preprocess | Actual input |

|---|---|---|---|

id |

9 | 9 | |

vol_i |

2 | 2 | |

vol_j |

7 | 7 | |

door |

2.2 | 2.20 | |

opening_latency |

Default to zero | 0 | |

vent_area_i_to_j |

Default to zero | 0 | |

opening_pressure_i_to_j |

Default to zero | 0 | |

opening_time_i_to_j |

Default to zero | 0 | |

cp_i_to_j |

0.8 | 0.8 | |

vent_area_j_to_i |

0 | ||

opening_pressure_j_to_i |

Default to opening_pressure_i_to_j |

0 | |

opening_time_j_to_i |

Default to opening_time_i_to_j |

0 | |

cp_j_to_i |

Default to cp_i_to_j |

0.8 | |

comments |

Default to null string | “” | |

ovar |

Default to zero | 0 | |

exvar |

Default to zero | 0 |

Simple decompressing door¶

A decompressing door is considered to clear its full frame area when the \(\Delta_P\) reach the triggering pressure. For an opened-door initial condition run, the decompressing feature will not be active, since the door itself is already opened.

This kind of decompression item is usually not symmetric: the static door frame allows the door to rotate only in one direction.

Example: The same example as above is used, except that the door is able

to open from 7 to 2 when \(\Delta_P\) reaches 1.5bar. Additionnally, an

opening time of 0.3 seconds will be used. Will still need to set the discharge

coefficient for i_to_j since the door will be opened for the opened-door

initial conditions.

| Column | User input | Preprocess | Actual input |

|---|---|---|---|

id |

9 | 9 | |

vol_i |

2 | 2 | |

vol_j |

7 | 7 | |

door |

2.2 | 2.20 | |

opening_latency |

Default to zero | 0 | |

vent_area_i_to_j |

Default to zero | 0 | |

opening_pressure_i_to_j |

Default to zero | 0 | |

opening_time_i_to_j |

Default to zero | 0 | |

cp_i_to_j |

0.8 | 0.8 | |

vent_area_j_to_i |

2.2 | 2.2 | |

opening_pressure_j_to_i |

1.5 | 1.5 | |

opening_time_j_to_i |

0.3 | 0.3 | |

cp_j_to_i |

Default to cp_i_to_j |

0.8 | |

comments |

Default to null string | “” | |

ovar |

Default to zero | 0 | |

exvar |

Default to zero | 0 |

Door nesting a decompression panel¶

Contrary to the example above (simple-decompressing-door), the door has no decompression mechanism, but hosts a nested decompression panel (cf. Fig. 5.11).

For illustration purposes, and to keep a certain level of complexity, the nested panel is considered blind –opening only from volume 2 to volume 7– which is not common.

The door itself will not be triggered with maximum Δp. However its 1.05m² nested panel will, only from volume 2 to volume 7.

Values for i_to_j data has to be filled, and values for j_to_i as well,

but set to 0 to avoid symmetrization (at least for the vent_area),

as shown in Table 5.11).

Warning

It is often a bad idea to define the panel as another item (another row) as the door. Indeed, in the latter case, during an opened-door load case, the panel will still be active and may be triggered, adding a new vent area that shouldn’t be!

| Column | User input | Preprocess | Actual input |

|---|---|---|---|

id |

9 | 9 | |

vol_i |

2 | 2 | |

vol_j |

7 | 7 | |

door |

2.2 | 2.20 | |

opening_latency |

Default to zero | 0 | |

vent_area_i_to_j |

1.05 | 1.05 | |

opening_pressure_i_to_j |

1.5 | 1.5 | |

opening_time_i_to_j |

0.3 | 0.3 | |

cp_i_to_j |

0.8 | 0.8 | |

vent_area_j_to_i |

0 | 0 | |

opening_pressure_j_to_i |

Default to opening_pressure_i_to_j |

1.5 | |

opening_time_j_to_i |

Default to opening_time_i_to_j |

0.3 | |

cp_j_to_i |

Default to cp_i_to_j |

0.8 | |

comments |

Default to null string | “” | |

ovar |

Default to zero | 0 | |

exvar |

Default to zero | 0 |

5.6. tab “Dyn_Attributes”¶

This tab is optional.

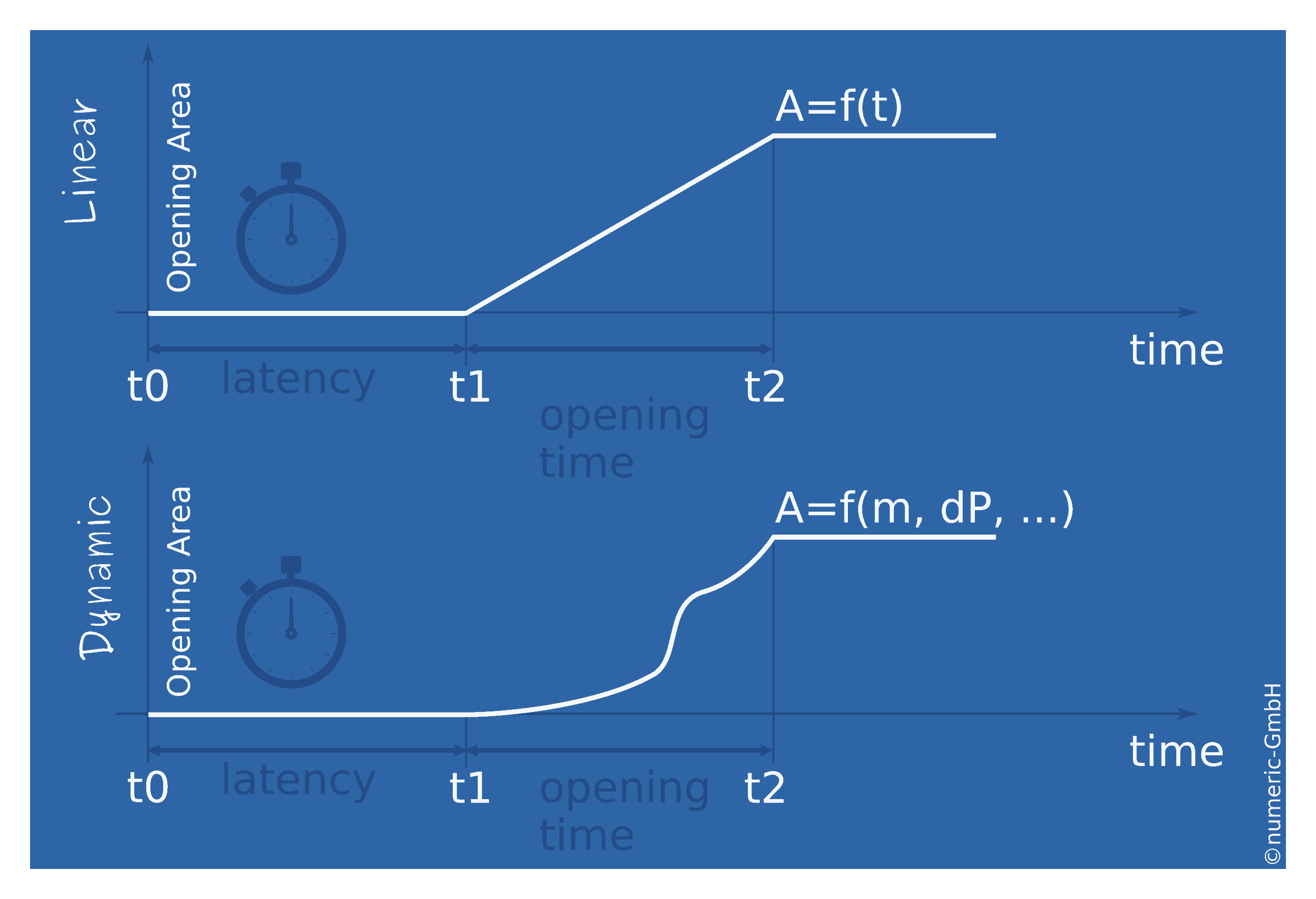

As of version 2, ESonix is able to dynamically compute the opening of a decompression feature. This means that there is no need to calculate the opening time based on an averaged DeltaP, the opening will be calculated step by step, using the actual pressure applied on the item.

This is a major asset in reaching precision for opening times, and therefore for the whole simulation.

To keep consistancy with previous versions and for retro compatibility, this new feature is optional.

Setting dynamical attributes to existing defined connections consists in

describing those dynamical attributes in an additional tab: dyn_attributes.

Linear opening time vs. Dynamic opening time¶

The “Dyn_Attributes” optional tab completes (and sometimes supersedes) the “Connections” tab.

It aims to provide accurate opening behaviour by taking into account the item’s mass, actual differential pressure, and many other parameters.

Fig. 5.12 Linear vs. dynamic opening time

Parameters¶

| description | default | units | |

|---|---|---|---|

| id | Connection ID | mandatory | no units |

| axis | Panel’s configuration | mandatory | no units |

| a | Panel’s length | mandatory | [m | in] |

| b | panel’s width | mandatory | [m | in] |

| mass | Panel’s mass | mandatory | [kg | lbs] |

| thk | Panel’s thickness | 0 | [m | in] |

| cx | Panel’s drag coefficient | 0 | no units |

| cos_ij_g | Cosinus of the angle between normal to panel and gravity (-z) | 0 | no units |

| max_distance_i_to_j | Panel’s max opening distance from i to j | 1000 | [m | in] |

| max_distance_j_to_i | Panel’s max opening distance from j to i | 1000 | [m | in] |

| max_angle_i_to_j | Panel’s max opening angle from i to j | 90 | [deg] |

| max_angle_j_to_i | Panel’s max opening angle from j to i | 90 | [deg] |

| prestress | Panel’s hinge prestress | 0 | [N/deg | lbf/deg] |

| stiffness | Panel’s hinge stiffness | 0 | [N/deg | lbf/deg] |

| damping | Panel’s hinge damping | 0 | [N/deg/sec | lbf/deg/sec] |

| cp_sin_theta | Panel’s variable discharge coefficient | 0 | no units |

| nb_rotating_ext | Number of opened triangles to take into account | 0 | no units |

| following_pressure | Wether or not pressure is following the panel | 1 | no units |

| opening_area_method | Method to caclulate the opening area as a function of opening angle | 0 | no units |

Dyn_Attributes/id¶

flags:

- Type: Int in range [0; +∞]

- Default: None

- Mandatory: True

- Unique: True

Short description:

Connection ID [no units]

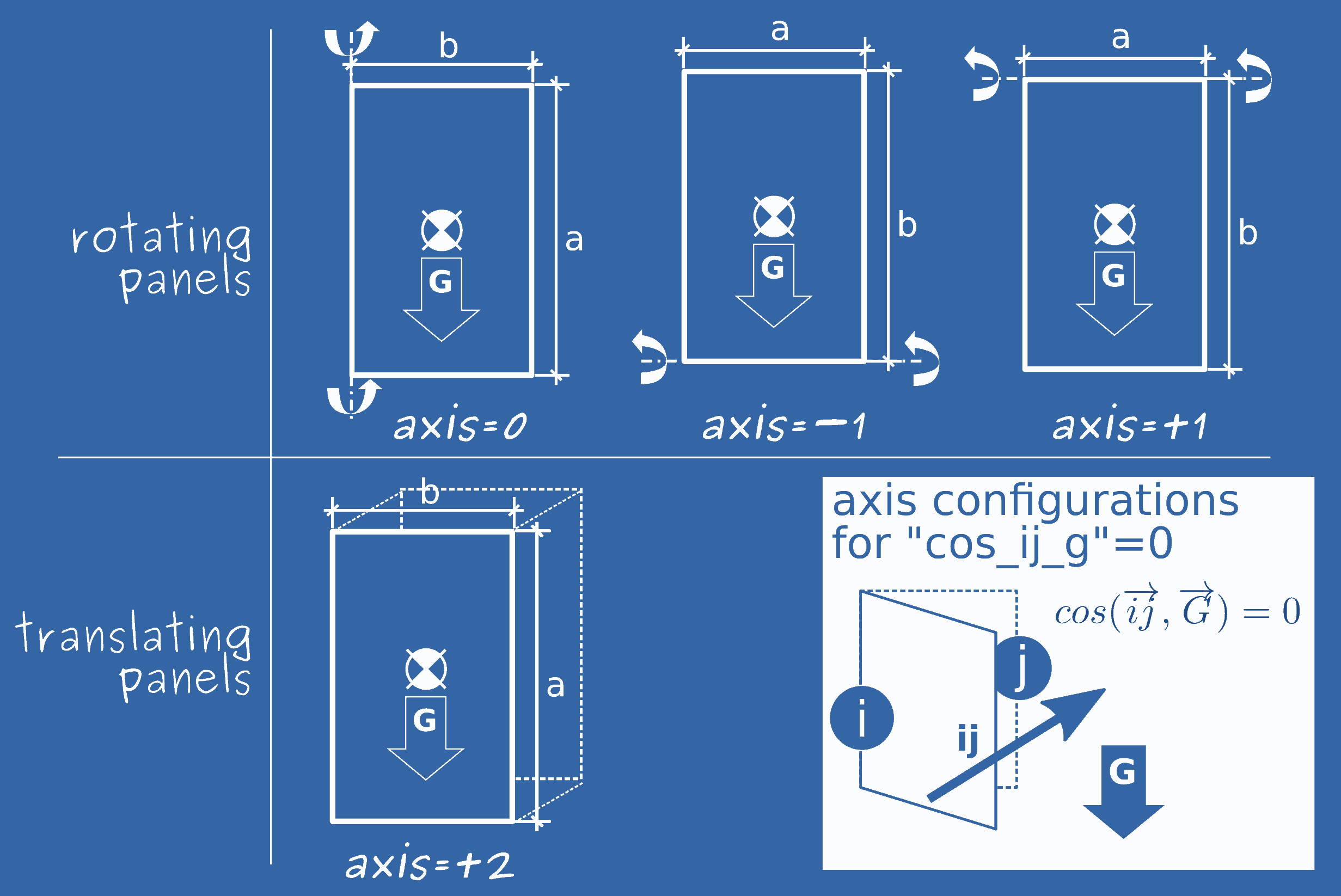

Dyn_Attributes/axis¶

flags:

- Type: Int in range [-1; 2]

- Default: None

- Mandatory: True

- Unique: False

Short description:

Panel’s configuration [no units]

The axis parameter describes the topology of the panel. axis may take

integer values from -1 to 2, as per the following rules:

| axis=-1: | Hinged panel rotating around bottom edge a |

|---|---|

| axis=0: | Hinged panel rotating around side a |

| axis=1: | Hinged panel rotating around top edge a |

| axis=2: | Translating panel |

Note

For hinged panels (-1<= axis <= 1 ), panel is always

articulated around edge a. axis is then used to determine

the work of the gravity.

Fig. 5.13 Axis parameter for cos(ij,G)=0

Dyn_Attributes/a¶

flags:

- Type: Float in range ]0; +∞]

- Default: None

- Mandatory: True

- Unique: False

Short description:

Panel’s length [m] or [in]

In case of rotating panel, a is the item’s length along the rotation axis. For translating panels, the orientation a vs. b does not impact the calculations.

Warning

Opening area defined by a x b will ovrewrite any opening area defined in the Connections tab for the current connection ID.

Dyn_Attributes/b¶

flags:

- Type: Float in range ]0; +∞]

- Default: None

- Mandatory: True

- Unique: False

Short description:

panel’s width [m] or [in]

In case of rotating panel, b is the item’s length perpendicular to the rotation axis. For translating panels, the orientation a vs. b does not impact the calculations.

Warning

Opening area defined by a x b will ovrewrite any opening area defined in the Connections tab for the current connection ID.

Dyn_Attributes/mass¶

flags:

- Type: Float in range [0; +∞]

- Default: None

- Mandatory: True

- Unique: False

Short description:

Panel’s mass [kg] or [lbs]

Dyn_Attributes/thk¶

flags:

- Type: Float in range [0; +∞]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Panel’s thickness [m] or [in]

The optional thickness parameter (defaulted to 0) has no impact on the panel’s inertia. This parameter is only used to take into account panel’s thickness in term of opening area latency (ie. A flat panel will release a vent area as soon as it starts to open, whereas a thick panel will require a small angle movement before disengaging).

Dyn_Attributes/cx¶

flags:

- Type: Float in range [0; 1.5]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Panel’s drag coefficient [no units]

This optional parameter is set to 0 by default. A 0 value means that air resistance is not taken into account. Any other value would lead to an air resistance according to this drag coefficient.

A value of 1.4 is common for thin rectangular shape.

Dyn_Attributes/cos_ij_g¶

flags:

- Type: Int in range [-1; 1]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Cosinus of the angle between normal to panel and gravity (-z) [no units]

Dyn_Attributes/max_distance_i_to_j¶

flags:

- Type: Float in range [0; +∞]

- Default: 1000

- Mandatory: False

- Unique: False

Short description:

Panel’s max opening distance from i to j [m] or [in]

Dyn_Attributes/max_distance_j_to_i¶

flags:

- Type: Float in range [0; +∞]

- Default: 1000

- Mandatory: False

- Unique: False

Short description:

Panel’s max opening distance from j to i [m] or [in]

Dyn_Attributes/max_angle_i_to_j¶

flags:

- Type: Float in range [0; +∞]

- Default: 90

- Mandatory: False

- Unique: False

Short description:

Panel’s max opening angle from i to j [deg]

Dyn_Attributes/max_angle_j_to_i¶

flags:

- Type: Float in range [0; +∞]

- Default: 90

- Mandatory: False

- Unique: False

Short description:

Panel’s max opening angle from j to i [deg]

Dyn_Attributes/prestress¶

flags:

- Type: Float in range [-∞; +∞]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Panel’s hinge prestress [N/deg] or [lbf/deg]

Dyn_Attributes/stiffness¶

flags:

- Type: Float in range [0; +∞]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Panel’s hinge stiffness [N/deg] or [lbf/deg]

Dyn_Attributes/damping¶

flags:

- Type: Float in range [0; +∞]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Panel’s hinge damping [N/deg/sec] or [lbf/deg/sec]

Dyn_Attributes/cp_sin_theta¶

flags:

- Type: Float in range [0; 1]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Panel’s variable discharge coefficient [no units]

cp_sin_theta allows the user to set up a variable discharge coefficient, as

presented [DS10] (page 497):

Where:

- \(C_D(\theta)\): Variable discharge coefficient function of opening angle

- \(C_{D0}\): Constant discharge coefficient defined in tab

connections cp_sin_theta: Variable discharge coefficient factor

Note

By default, cp_sin_theta is null, therefore, discarge coefficient is fixed

and defined from the connections tab only.

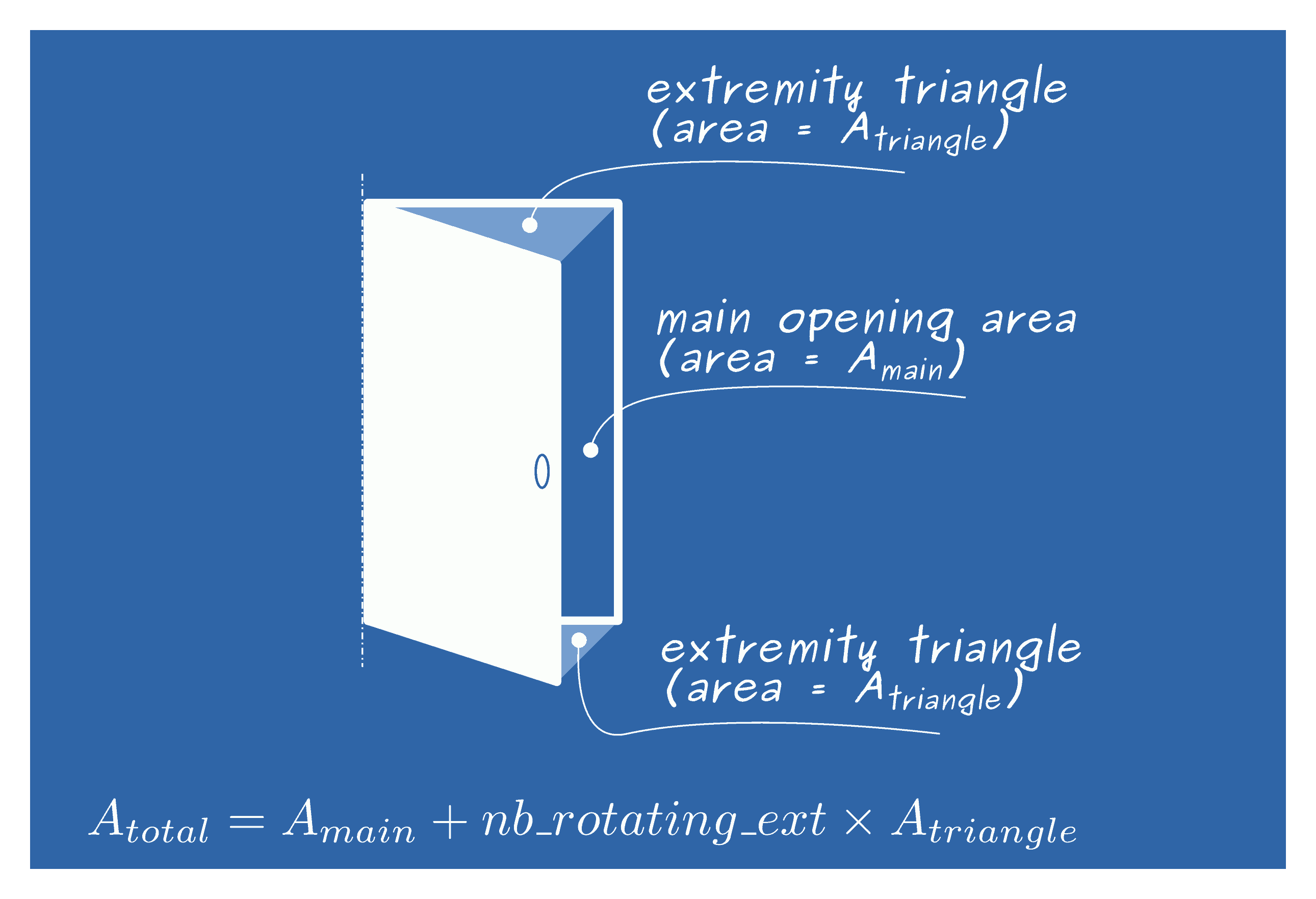

Dyn_Attributes/nb_rotating_ext¶

flags:

- Type: Int in range [0; 2]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Number of opened triangles to take into account [no units]

nb_rotating_ext is only used for rotating panels and defines the number

of “triangles” to take into account for calculating the resulting

opening area. For example, a regular door flush with floor and with a

large gap with ceilings would clear one “triangle” at the top.

A door flush with floor and ceilings would have no “triangles” opened.

Fig. 5.14 Influence of the number of opened triangles for opening area

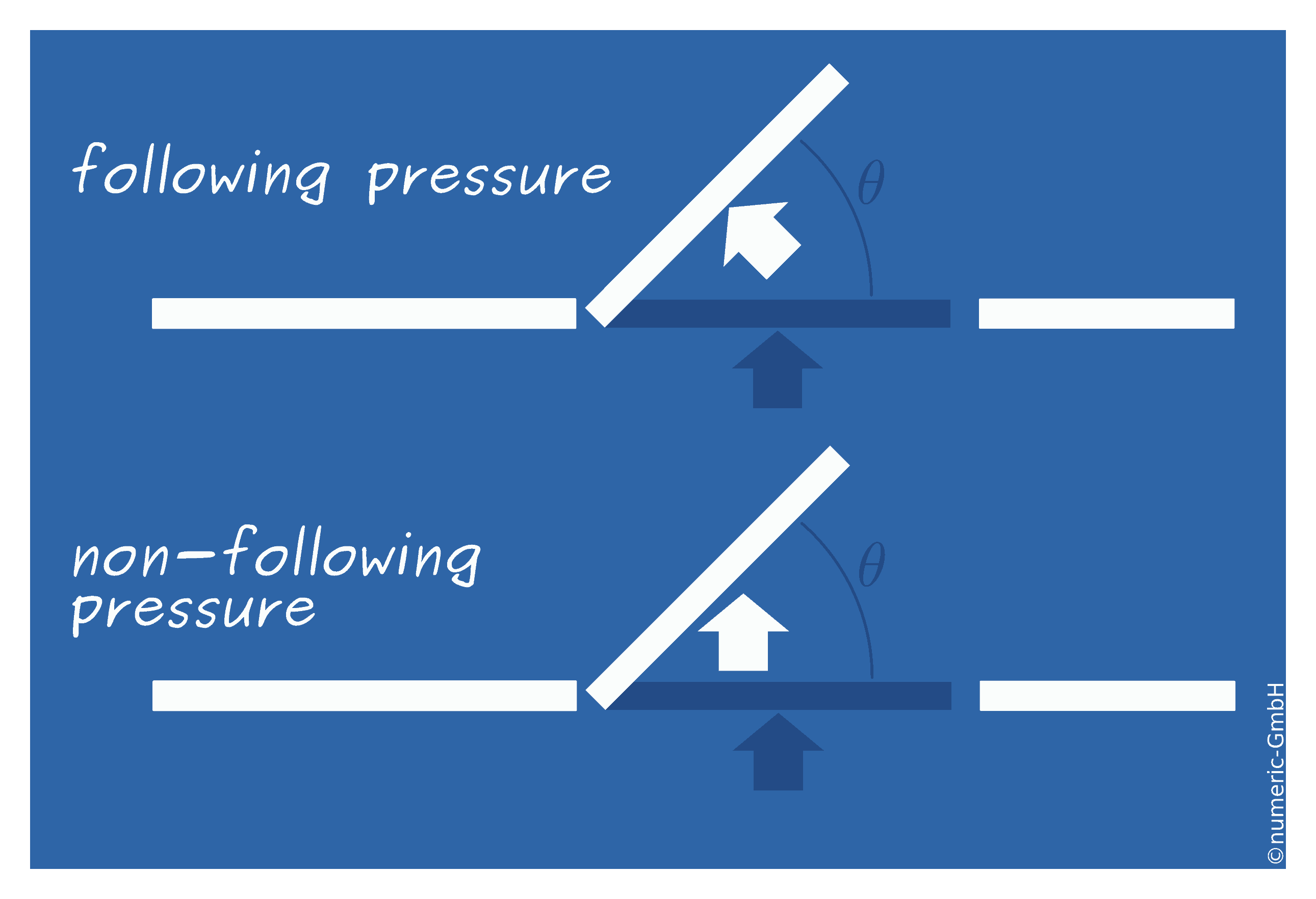

Dyn_Attributes/following_pressure¶

flags:

- Type: Int in range [0; 1]

- Default: 1

- Mandatory: False

- Unique: False

Short description:

Wether or not pressure is following the panel [no units]

following_pressure is only relevant for rotating panels.

following_pressure=1(default and recommended): the pressure is “following” the item, behaving as a static pressure. This method is recommended by SAE in [SAE10].following_pressure=0: the pressure remains “perpendicular to the initial item’s area”, behaving as a dynamic pressure. This method is recommended by Pagani & Carrera in [PC16].

Fig. 5.15 Following pressure vs. non-following pressure

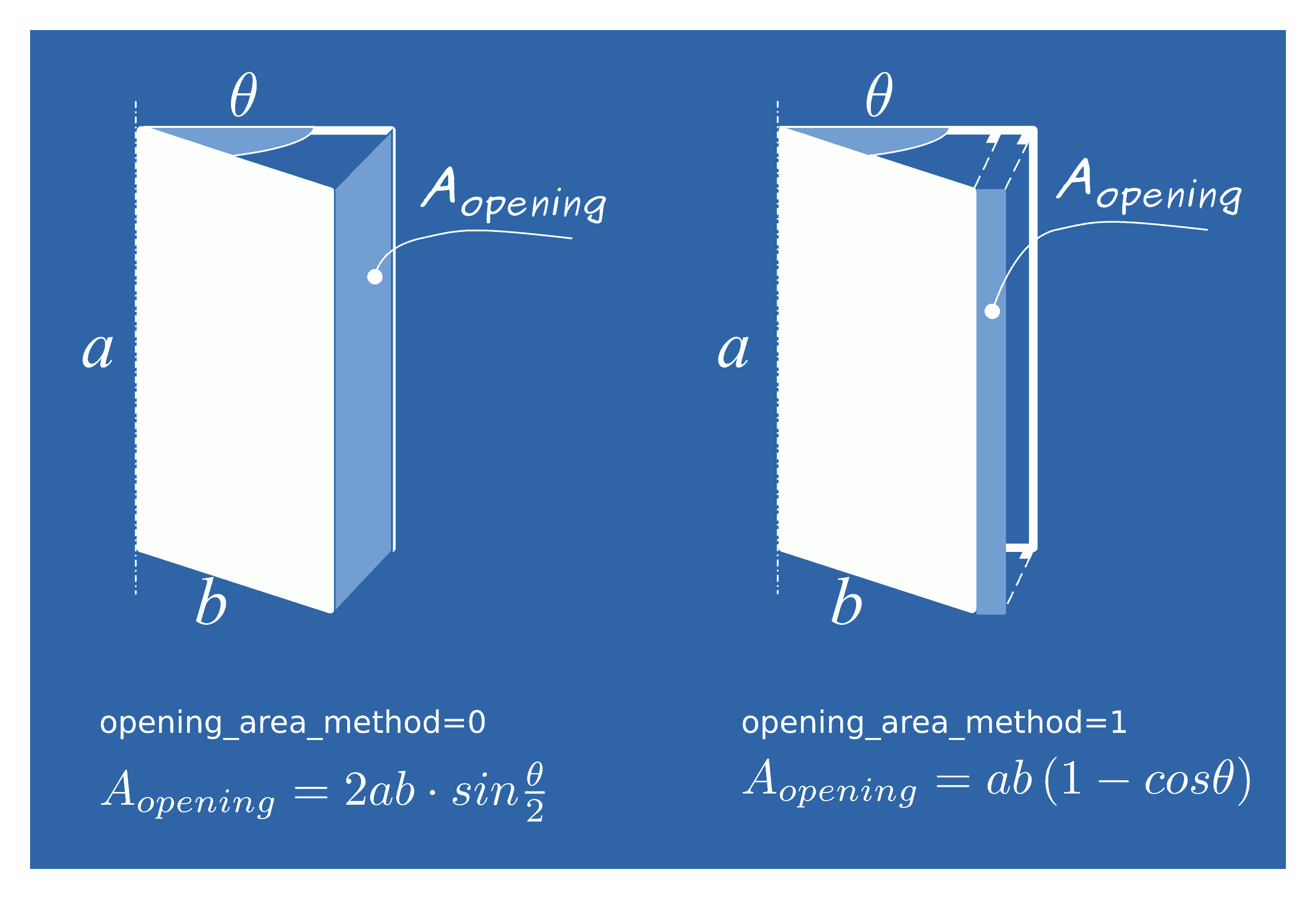

Dyn_Attributes/opening_area_method¶

flags:

- Type: Int in range [0; 1]

- Default: 0

- Mandatory: False

- Unique: False

Short description:

Method to caclulate the opening area as a function of opening angle [no units]

opening_area_method is only used for rotating panels and defines the

method to calculate the opening area. The default is zero.

opening_area_method=0(recommended method): the opening area (with exclusion of top and bottom triangles) is the rectangle defined by the distance “a” multiplied by the distance between the external edge of the panel and its frame. This is the recommended method for ESonix, and the method proposed bye SAE in [SAE10], and Daidzic and Simones in [DS10].opening_area_method=1: the opening area (with exclusion of top and bottom triangles) is the projection of the opening area as defined withopening_area_method=0onto the frame’s plan. This is the method proposed by Pagani & Carrera in [PC16].

Fig. 5.16 Calculation methods for the opening area (rotating panels only)

Footnotes

| [1] | The value is mandatory, and has therefore no default value. |

| [2] | Values are excluding each other. Only one of them need to be filled. |

| [3] | This value will not affect calculations, but is used to present results in a comprehensive way. An accurate value is therefore not useful. |

| [4] | symmetrized from <var>_i_to_j. |

| [5] | Only used for rotating (hinged) panels ( -1 <= axis <= 1) |